(CC) - Generic Rigid Core Luxury Vinyl Running Line 5.0mm 12mil

Our Generic Rigid Core Luxury Vinyl Running Line offers superior quality and enduring appeal, providing a reliable and beautiful flooring solution for any residential space. Featuring an enhanced 5.0mm thickness and a tough 12-mil wear layer, this plank is exceptionally reliable for high-traffic and high-moisture areas like family rooms, kitchens, and entryways. Along with sophisticated, realistic wood-look visuals, rich tones, and detailed textures, this collection is engineered with core technology that guarantees 100% waterproof protection and remarkable resistance to scratches, scuffs, and impact dents.

Your choice for easy,

DIY-friendly installation, long-lasting comfort, and exceptional lifetime value!

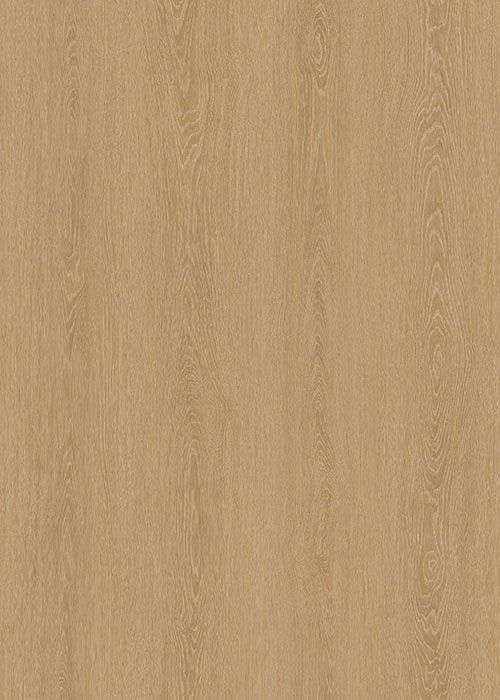

CC001 Laurel Springs

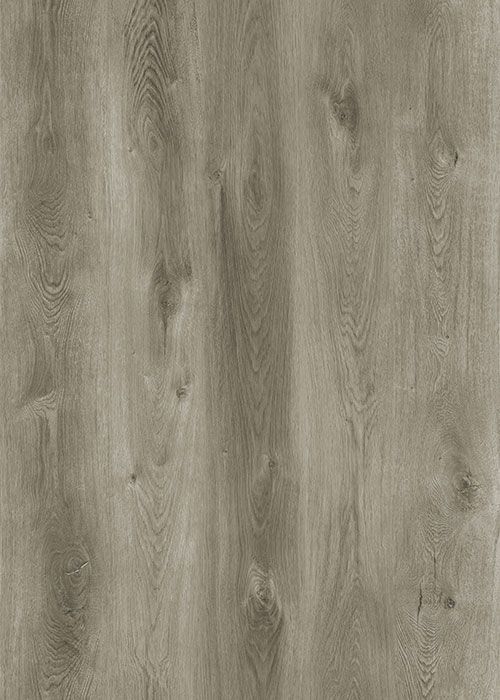

CC002 Sandy Point

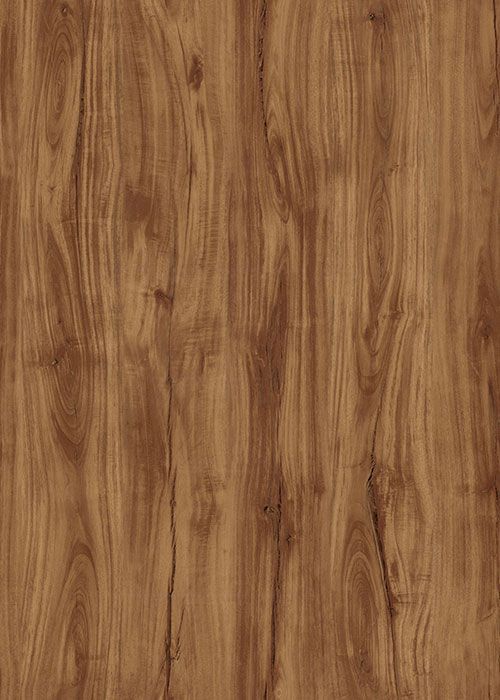

CC003 Harmony

CC004 Golden Coast

CC005 Hope Springs

CC006 Rosemary

CC007 Heritage

CC008 Redwood Falls

CC009 Clear Lake

CC010 Avalon

CC007 Heritage

CC011 Regent

CC012 Timber Lake

Specifications

Technical Data

| Column 1 | Column 2 | Column 3 | Column 4 |

|---|---|---|---|

| Length | 48.03 | Width | 7.17 |

| Thickness | 5mm | Wear Layer | 12mil |

| Finishing | Random EIR | Edge Description | Micro Bevel |

| Sqft/Box | 28.68 | lb/Box | 49.4 |

| Box/Plt | 55 | Sqft/Plt | 1577 |

| lb/Plt | 2745 | Plt/FTL | 16 |

| Limited Residential Warranty | Lifetime | Limited Commercial Warranty | 10Years |

| No. | Description | Method | Standard | Result | Performace Rating |

| 1 | Packing Appearance | Internal | Pallets/Cartons/Labels/Inserts/Bar Codes match customer order in quality and quantity, with neat appearance. | Pass | Better |

| 2 | Product Appearance | Internal | Material must match customer order. No print film folding, no rough bevel, no bevel with white line, no film scratch or breakage, no color difference, no wear layer bubbles, no impurities, no stains, no dents, no scratches, no broken corners, no fish eyes, no trash, no holes, no hair/ foreign subject, no overhang or uneven backpad, etc. | Pass | Better |

| 3 | Dimensions | ASTM F1700 | ± 0.40 mm ± 0.10 mm | 0.03mm 0.02mm | Best Best |

| 4 | Overall Thickness | ASTM F1700 | ± 0.10 mm | 0.02mm | Best |

| 5 | Squareness | ISO 24342 | ≤ 0.25 mm ≤ 0.25 mm | 0.03mm 0.02mm | Best Best |

| 6 | Straightness | ISO 24342 | ≤ 0.25 mm ≤ 0.25 mm | 0.05mm 0.01mm | Best Best |

| 7 | Stitching Gap (mm) | EN13329 | ≤ 0.10mm | 0.02mm | Best |

| 8 | Height Difference | EN13329 | ≤ 0.10mm | 0.03mm | Best |

| 9 | Resilient floor covering Determination of peel resistance | EN ISO 24345:2012 | ≥54N/50mm | Longitudinal direction: 95N/50mm Cross direction: 95N/50mm | Best |

| 10 | Scratch Resistance | EN 16094B | > 2500g | 3,500g | Best |

| 11 | Micro-Scratch Resistance (A & B) | EN 16094 | MSR-B1 - B3 | MSR-B2 | Better |

| 12 | Coating Adhesion (Cross hatch) | EN 16094B | 5B | 5B | Best |

| 13 | Abrasion Resistance of Organic Coatings by the Taber Abraser | ASTM D4060 | No pass-fail criteria | Abrasion Wheel H-18 Load Applied 1000 Grams Number Of Cycles:14000 | Best |

| 14 | Locking strength | ISO 10582:2017 Annex D | Class 32, type I:≥1.5kN/m | Long side(X): 7.6 kN/m Short side(Y): 6.3 kN/m Pass | Best |

| 15 | Determination of dimensional stability and curling after exposure to heat | ISO 23999 ASTM F3261 | Length mean≦0.25% Width mean≦0.25% The curling≦2mm | Length mean = -0.05% Width mean = 0% The curling = 0mm | Best |

| 16 | Wear Layer Abrasion Resistance | EN 13329 (S-42, 200 cycle change) | IP≥2000 cycles | 2400 cycles Abrasion Class: >AC3 | Better |

| 17 | Density | ASTM D2395 | 1.9-2.2g/cm³ | 1.98g/cm³ | Good |

| 18 | Phthalate tests (DBP/BBP/DEHP/DINP/ DNOP/DIDP) | EN 14372:2004 | N/A | Free | Best |

| 19 | Heavy Metal Content Analysis | ASTM F963-16(Clause 8.3) | Antimony < 60 ppm, Arsenic < 25 ppm, Barium < 1000 ppm, Cadmium < 75 ppm, Chromium < 60 ppm, Lead < 90 ppm, Mercury < 60 ppm, and Selenium < 500 ppm | Free | Best |

| 20 | Gloss Level (gu) | ASTM D523 | ±2gu | < ±2gu | Good |

| 21 | Resistance to Chemicals | ASTM F925 | 0 - No change (----) 1 - Slight change 2 - Moderate change 3 - Severe change | 0 No Change | Good |

| 22 | Determining Resistance of Synthetic Polymers to Fungi | ASTM G21 | Rating 0: No Fungal Growth on Sample Rating 1: Trace of Growth (< 10% coverage) Rating 2: Light Growth (10-30% coverage) Rating 3: Medium Growth (30-60% coverage) Rating 4: Heavy Growth (60-100% coverage) | Rating 0, No Fungal Growth on Sample | Best |

| 23 | Smoke Density (Non-Flaming) | ASTM E662 | ≦450 | 291 | Best |

| 24 | Smoke Density (Flaming) | ASTM E662 | ≦450 | 237 | Best |

| 25 | Calculated Sound Transmission (STC) | ASTM E90-09 (2016) ASTM E413-16 | No pass-fail criteria | 52 | Good |

| 26 | Residual indentation | ASTM F1700-13a & ASTM F1914-07(2011) | Average value≦8% Individual value≦10% | 0.40% | Best |

| 27 | Determination of Indentation and Residual Indentation | ISO 24343-1:2012 | N/A | 0mm | Best |

| 28 | Static Load | ASTM F970-17 | N/A | 0.04mm | Good |

| 29 | Heat Stability of Resilient Flooring by Color change | ASTM F1514 | < 8.0 ΔE | ΔE=0.67 | Best |

| 30 | Light Stability of Resilient Flooring by Color change | ASTM F1515 | < 8.0 ΔE | 0.29-0.46 ΔE | Best |

| 31 | Static Coefficient of Friction | ASTM C1028 | ≥ 0.60 for dry surfaces ≥ 0.53 for wet surfaces | Dry 0.69 Wet 0.56 with 50lbs load | Good |

| 32 | Fire resistance | EN 9239-1 EN ISO11925-2 EN 13501-1 | Critical Fluxf≥8.0kW/m² Fs≤150mm within 20s Smoke≤750% minutes | Bfl-S1 | Better |

| 33 | Formaldehyde Emission | ISO 17226-1:2008 | N/A | Free | Best |

| 34 | Slip resistance | EN13893 | N/A | Class DS | Good |

| 35 | Slip resistance (oil-wet ramp test) | DIN 51130:2014-02 | N/A | Critical angle of inclination: 14.8°Classification: R10 Pass | Good |

| 36 | Large ball impact resistance | NALFA/ANSI LF-01-2011 | N/A | No cracks or fractures occurred at the height of 2500mm | Best |

| 37 | Static Electrical Propensity | EN 1815:2016 method A | ≦2kV | 0.2kV | Best |

| 38 | Surface Bond | NALFA/ANSI LF-01-2011 | N/A | 1.14MPa | Good |

| 39 | Thermal conductivity | EN 12667:2001 | N/A | 0.154 W/(m.K) | Best |

| 40 | Thermal Resistance | EN 12667:2001 | N/A | 0.033(m2.K)/W | Best |

| 41 | Colour Fastness | EN ISO 105-B02:2014 | N/A | Grade 6 | Good |