Premium Rigid Core 8mm 28mil SHIELD4MAX™

Rigid Core PA collection is designed for commercial spaces and high-end residential homes with unprecedented durability, unmatched beauty and effortless maintenance. Explore the multiple incomparable features of your life-lasting and resilient flooring choice !!

● Enhanced with proprietized & innovative SHIELD4MAX™ technology which was built in the planks with 100% waterproof, unparalleled scratch-shield, stain-shield and bacteria-shield performance.

● Luxury extra-long and ultra-wide planks with painted bevels and Embossed-In-Register technology which intensifies the depth, texture and authentic wood look of the flooring.

● Ultra thick core and exceptional dense sound pad enable the installed planks with increased sound-proof performance.

● Specially designed to endure heavy everyday foot traffic with extreme performance, this collection suits to high-traffic commercial spaces incl. corporate offices, banks, hotels and other commercial buildings.

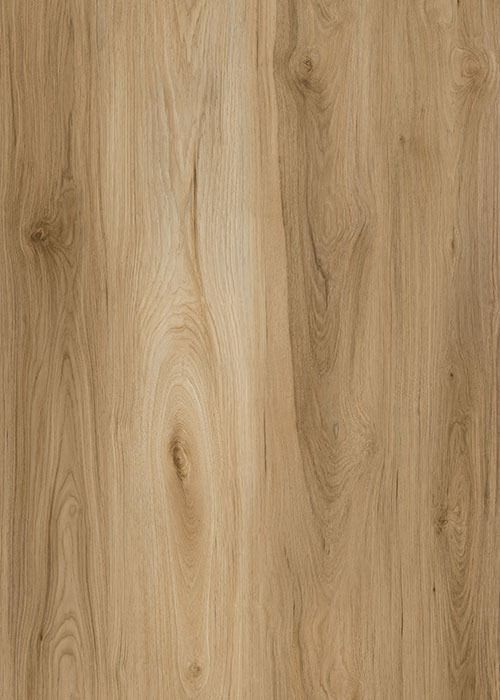

PA801 Coastal Dunes

PA802 Royal Sands

PA803 Prestige Oak

PA804 Reina Oak

PA805 Winery Oak

PA806 Melrose

PA807 Chardonnay

PA808 Biltmore

Specifications

Technical Data

| Length | 60" | Width | 9.06" |

|---|---|---|---|

| Thickness | 8.0mm | Wear Layer | 28mil |

| Finish | EIR | Edge Description | Painted Bevel |

| Sqft/Box | 18.87 | lb/Box | 48.6 |

| Box/Plt | 52 | Sqft/Plt | 981.24 |

| lb/Plt | 2527.2 | Plt/FTL | 17 |

| Limited Residential Warranty | Lifetime | Limited Commercial Warranty | 20 Years |

| No. | Description | Method | Standard | Result | Performace | |

|---|---|---|---|---|---|---|

| Rating | ||||||

| 1 | Packing Appearance | Internal | Pallets/Cartons/Labels/Inserts/Bar Codes match customer order in quality and quantity, with neat appearance. | Pass | Better | |

| 2 | Product Appearance | Internal | Material must match customer order. | Pass | Better | |

| No print film folding, no rough bevel, no bevel with white line, no film scratch or breakage, no color difference, no wear layer bubbles, no impurities, no stains, no dents, no scratches, no broken corners, no fish eyes, no trash, no holes, no hair/ foreign subject, no overhang or uneven backpad, etc. | ||||||

| 3 | Dimensions | Length | ASTM F1700 | � 0.40 mm | 0.03mm | Best |

| Width | � 0.10 mm | 0.02mm | Best | |||

| 4 | Overall Thickness | ASTM F1700 | � 0.10 mm | 0.02mm | Best | |

| 5 | Squareness | Length | ISO 24342 | ? 0.25 mm | 0.03mm | Best |

| Width | ? 0.25 mm | 0.02mm | Best | |||

| 6 | Straightness | Length | ISO 24342 | ? 0.25 mm | 0.05mm | Best |

| Width | ? 0.25 mm | 0.01mm | Best | |||

| 7 | Stitching Gap (mm) | EN13329 | ? 0.10mm | 0.02mm | Best | |

| 8 | Height Difference | EN13329 | ? 0.10mm | 0.03mm | Best | |

| 9 | Wear Layer | EN 429 | � 0.02 mm | 0.01mm | Best | |

| Thickness | ||||||

| 10 | Resilient floor covering Determination of peel resistance | EN ISO 24345:2012 | ?54N/50mm | Longitudinal direction:91.3N/50mm | Best | |

| Cross direction:91.3N/50mm | ||||||

| 11 | Scratch Resistance | EN 16094B | > 2500g | 3,800g | Best | |

| 12 | Micro-Scratch | EN 16094 | MSR-B1 - B3 | MSR-B1 | Best | |

| Resistance (A & B) | ||||||

| 13 | Coating Adhesion | EN 16094B | 5B | 5B | Best | |

| (Cross hatch) | ||||||

| 14 | GreenGuard Gold Certified | UL 2818 - 2013 | Refer to Standards | Pass | Best | |

| Gold Standard for Chemical Emissions for Building Materials, Finishes and Furnishings | ||||||

| 15 | Floorscore Certification | SCS-EC10.3-2014v3.0 | Refer to Standards | Pass | Best | |

| 16 | CE Certification | EN14041 | Refer to Standards | Pass | Best | |

| 17 | Fire resistance | EN 9239-1 | Critical Fluxf?8.0kW/m2 | Bfl-S1 | Better | |

| EN ISO11925-2 | Fs?150mm within 20s | |||||

| EN 13501-1 | Smoke?750% minutes | |||||

| 18 | Phthalate tests | EN 14372:2004 | N/A | Free | Best | |

| (DBP/BBP/DEHP/DINP/DNOP/DIDP) | ||||||

| 19 | Dimension stability | EN ISO23999:2012 | ?0.25% | Manufacturing direction:-0.04% | Best | |

| Across-manufacturing direction:-0.01% | ||||||

| 20 | Seam strength | EN 684:1995 | N/A | Ave.:360N/50mm Pass | Best | |

| Min.:330N/50mm | ||||||

| 21 | Residual indentation (%) | ISO24343-1:2007 | Average value?8 | 0.19 Pass | Best | |

| Individual value?10 | ||||||

| 22 | Resistance to chemicals | ASTM F1700-13a & | No more than a slight change in | No change in surface dulling,surface attack,or staining was detected | Best | |

| ASTM F925-13 | surface dulling, surface attack,or staining | |||||

| 23 | Heat stability | ASTM F1514-03(R2013) | ?E*ab< 8 | ?E*ab=0.67 Pass | Better | |

| 24 | Static loading | ASTM F970-17 | N/A | 0.04mm Pass | Better | |

| 25 | Soluble heavy metal contents test | EN71-3:2019 | N/A | Free | Best | |

| 26 | Large ball impact resistance | NALFA/ANSI LF-01-2011 | N/A | No cracks or fractures occurred at the height of 2500mm | Best | |

| 27 | Static Electrical Propensity | EN 1815:2016 method A | ?2kV | 0.5kV | Best | |

| 28 | Airborne Sound Transmission | ASTM E90-23 | N/A | STC = 68 | Best | |

| Loss Test and Class | ASTM E413-22 | |||||

| 29 | Determination of Impact | ASTM E492-22 | N/A | IIC = 67 | Best | |

| Sound Insulation Class | ASTM E989-21 | |||||

| 30 | Formaldehyde | EN 13986:2004+A1:2015 | N/A | Free | Best | |

| 31 | Surface Bond | NALFA/ANSI LF-01-2011 | N/A | 1.14MPa Pass | Best | |

| 32 | Castor chair Resistance(25000 Cycles) | NALFA/ANSI LF-01-2011 | N/A | No damage was found after test | Best | |

| ISO4918:2016 | ||||||

| 33 | Thermal conductivity | EN 12664:2001 | N/A | 0.122 W/(m.K) | Good | |

| 34 | Thermal Resistance | EN 12664:2001 | N/A | 0.054(m2.K)/W | Good | |

| 35 | Colour Fastness | EN ISO 105-B02:2014 | N/A | ?Grade 6 | Good | |

| 36 | Curling | ISO 23999:2012 | N/A | Average: 0.1mm Pass | Better | |

| 37 | Locking strength | ISO 10582:2017 Annex D | Class 32, type I:?1.5kN/m | Long side(X): 6.8 kN/m | Good | |

| Short side(Y): 6.8 kN/m Pass | ||||||

| 38 | Resistance to staining | EN423:2002 | N/A | Index 0: Not affected Pass | Best | |

| 39 | Slip resistance | DIN 51130:2014 | N/A | Critical angle of inclination: 10.8�Classification: R10 Pass | Good | |

| (oil-wet ramp test) | ||||||

| 40 | Resistance to bacteria | ISO 846-2019 Method C | N/A | Assessment of bacteria growth: 0 Pass | Best |