(SC) - Basic Rigid Core Running Line 4.5mm 12mil

Our Basic Rigid Core Running Line offers extraordinary value and effortless style, providing a dependable luxury vinyl plank for any new or existing floor. Featuring a robust 4.5mm thickness and a durable 12-mil wear layer, this floor is exceptionally friendly for high-moisture areas like bathrooms, kitchens, and basements. Along with stunning, authentic wood-look visuals, subtle tones, and crisp details, the collection is built with technology that ensures 100% waterproof performance and ultra-resistance to scratches, stains, and dents.

Your choice for easy, dust-free installation, remarkable durability, and affordable cost!

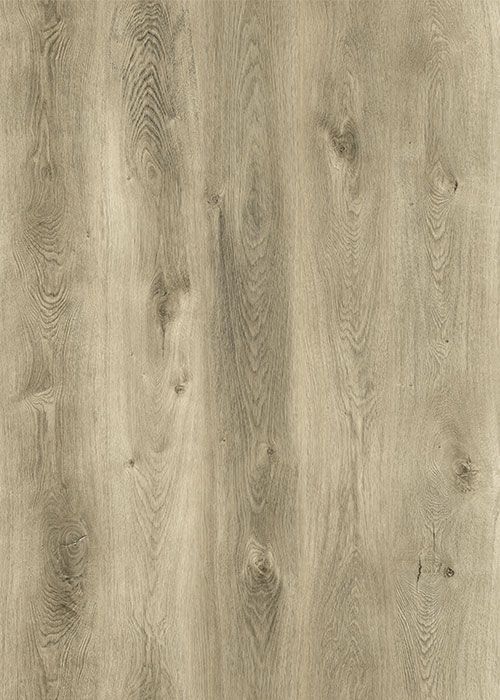

SC001 Mont Claire

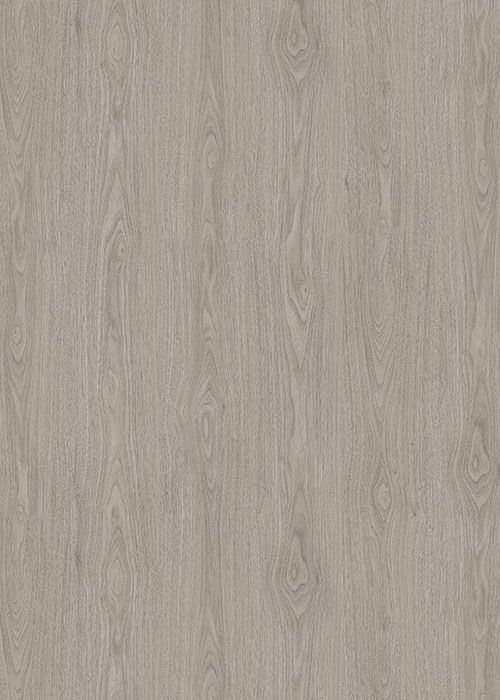

SC002 Woodmont

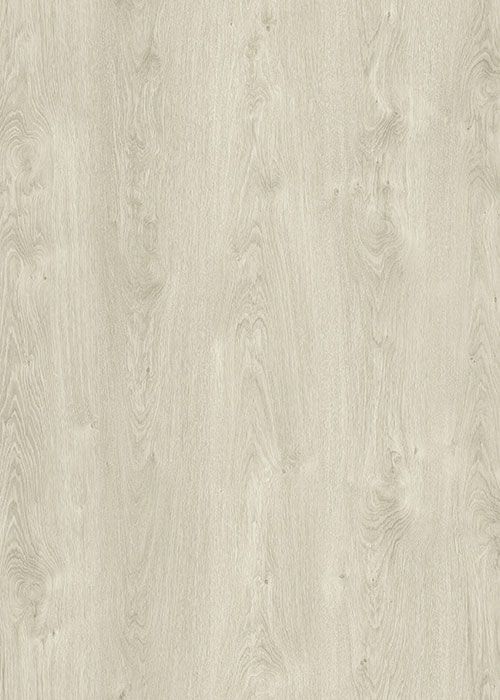

SC003 Yorkshire

SC005 Monroe

SC006 Westchester

SC007 Windermere

SC009 Sand Beach

SC011 Berkley Hill

SC012 Sydney Bay

Specifications

Technical Data

| Length | 48.03" | Width | 7.17" |

|---|---|---|---|

| Thickness | 4.5mm | Wear Layer | 12mil |

| Finish | Wood Emboss | Edge Description | Square |

| Sqft/Box | 28.68 | lb/Box | 43.2 |

| Box/Plt | 60 | Sqft/Plt | 1721 |

| lb/Plt | 2657 | Plt/FTL | 16 |

| Limited Residential Warranty | 10 Years |

| Items | Standards | Requirements | Result |

|---|---|---|---|

| Floorscore Certification | SCS-EC10.3-2014v3.0 | Refer to Standards | Pass |

| GreenGuard Gold Certified | UL 2818 - 2013 Gold Standard for Chemical Emissions for Building Materials, Finishes and Furnishings | Refer to Standards | Pass |

| CE Certification | EN14041 | Refer to Standards | Pass |

| Fire resistance | EN 9239-1 EN ISO11925-2 EN 13501-1 | Critical Fluxf≥8.0kW/m2 Fs≤150mm within 20s Smoke≤750% minutes | Bfl-S1 |

| Phthalate tests (DBP/BBP/DEHP/DINP/ DNOP/DIDP) | EN 14372:2004 | N/A | Free |

| Dimension stability | ASTM F2199-09(R2014) | ≦0.25% | Manufacturing direction:-0.046% Across-manufacturing direction:-0.009% |

| Determination of dimensional stability and curling after exposure to heat | ISO 23999:2012 | ≤0.25% The curling ≤ 2mm | MD:-0.05% AMD: 0% 0mm |

| Seam strength | EN 684:1995 | N/A | Ave.:360N/50mm Pass Min.:330N/50mm |

| Residual indentation (%) | ASTM F1700-13a & ASTM F1914-07(2011) | Average value≦8 Individual value≦10 | 0.4 Pass |

| Determination of Indentation and Residual Indentation | ISO 24343-1:2012 | N/A | 0mm Pass |

| Resistance to chemicals | ASTM F1700-13a & ASTM F925-13 | No more than a slight change in surface dulling,surface attack,or staining | No change in surface dulling,surface attack,or staining was detected |

| Heat stability | ASTM F1514-03(R2013) | △E*ab< 8 | △E*ab=0.67 Pass |

| Static loading | ASTM F970-17 | N/A | 0.04mm Pass |

| Soluble heavy metal contents test | ASTM F963-16(Clause 8.3) | N/A | Free |

| Large ball impact resistance | NALFA/ANSI LF-01-2011 | N/A | No cracks or fractures occurred at the height of 2500mm |

| Static Electrical Propensity | EN 1815:2016 method A | ≦2kV | 0.2kV |

| Formaldehyde | ISO 17226-1:2008 | N/A | Free |

| Surface Bond | NALFA/ANSI LF-01-2011 | N/A | 1.14MPa Pass |

| Resilient floor covering Determination of peel resistance | EN ISO 24345:2012 | ≥54N/50mm | Longitudinal direction:95N/50mm Cross direction:95N/50mm |

| Thermal conductivity | EN 12667:2001 | N/A | 0.154 W/(m.K) |

| Thermal Resistance | EN 12667:2001 | N/A | 0.033(m2.K)/W |

| Colour Fastness | EN ISO 105-B02:2014 | N/A | Grade 6 |

| Dimensional stability | ISO 23999:2008 | N/A | Average: X Direction: 0.02% Pass Y Direction: -0.06% |

| Curling | ISO 23999:2008 | N/A | Average: 0.5mm Pass |

| Residual indentation | ISO 24343-1:2007 | N/A | Average: 0.02mm Pass |

| Locking strength | ISO 10582:2017 Annex D | Class 32, type I:≥1.5kN/m | Long side(X): 7.6 kN/m Short side(Y): 6.3 kN/m Pass |

| Resistance to staining | ISO 26987:2008 | N/A | Index 0: Not affected Pass |

| Scratch Resistance | EN 16094B | >2,500g | 3,500g |