(WG) - Generic WPC Engineered Vinyl Running Line: 8.0mm 20mil

Our Generic WPC Engineered Vinyl Running Line delivers a new level of comfort and acoustic performance, offering a quiet, warm, and highly resilient flooring experience. Featuring an industry-leading 8.0mm overall thickness and a powerful 20-mil wear layer, this WPC plank is perfect for residential areas needing extra softness and warmth, like bedrooms, living areas, and home theaters. Along with elegant, high-definition wood-look visuals, fashionable tones, and authentic surface textures, this collection is built upon a wood-plastic composite core that ensures 100% waterproof capability, superior sound absorption, and outstanding defense against abrasion, temperature fluctuations, and everyday foot traffic.

Your choice for easy, click-together installation, maximum underfoot comfort, and exceptional acoustic value!

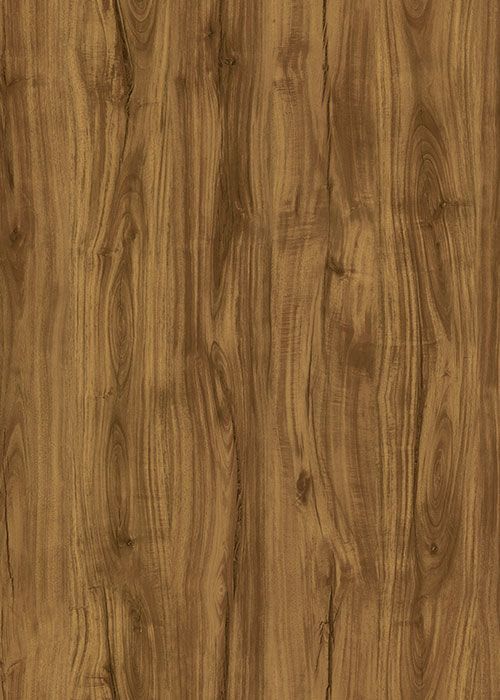

WG001 Ewa Beach

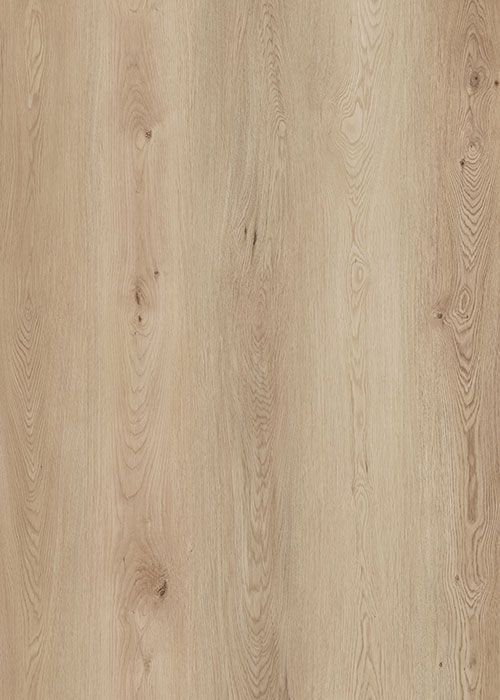

WG002 Belmont

WG003 Cheyenne

WG004 Lincoln

WG005 Fairview

WG006 Wyndmere

WG007 Springbrook

WG008 Gold Creek

Specifications

Technical Data

| Length | 60 | Width | 8.98 |

| Thickness | 8mm | Wear Layer | 20mil |

| Finishing | Handscrapped Emboss / Random EIR | Edge Description | Painted Bevel |

| Sqft/Box | 29.92 | lb/Box | 43.8 |

| Box/Plt | 44 | Sqft/Plt | 1317 |

| lb/Plt | 1994 | Plt/FTL | 22 |

| Limited Residential Warranty | Lifetime | Limited Commercial Warranty | 15Years |

| Characteristics | Standards | Requirements | Result |

|---|---|---|---|

| TUV Premium Certification | Belgian VOC regulation BREEAM Exemplary Leve | Refer to Standards | Pass |

| CE Certification | EN14041 | Refer to Standards | Pass |

| Floorscore Certification | SCS-EC10.3-2014v3.0 | Refer to Standards | Pass |

| Castor Chair Resistance | NALFA LF 01-2011 Section 3.9 | N/A | After 25000 cycles,test specimens no visible damage |

| Dimensional Stability | ASTM F2199-09(2014) Heating temperature:65oC | ≤0.25% | MD:=-0.092% AMD:=-0.030% |

| Pentachlorophenol(PCP) | With reference to PD CEN/TR 14823:2003 | N/A | Free |

| Formaldehyde Emission | EN 717-1:2004 | E1≤0.124mg/m³ | Free |

| Fire resistance | EN ISO 9239-1 EN ISO 11925-2 EN 13501-1:2010 | N/A | Bfl-S2 |

| Calculated Sound Transmission(STC) | ASTM E90-23 ASTM E413-22 | No pass-fail criteria | STC=68 |

| Impact Sound Reduction(IIC) | ASTM E492-22 ASTM E989-21 | No pass-fail criteria | IIC=68 |

| Impact resistance | ASTM F1265-03a(2013) | N/A | No crack |

| Phthalate tests (DBP/BBP/DEHP/DINP/ DNOP/DIDP) | REACH NO.1907/2006 | N/A | Free |

| Resistance to Heat | ASTM F1514-03(2013) | △E* shall not greater than 8.0 after7 days exposure to 70°C | △E*=0.66 |

| Residual indentation | ASTM F1914-07(2011) | Average≤8% Max≤10% | Average≤6.6% Max≤7.4% |

| Slip resistance | EN 13893:2003 | EN 14041:μ≥0.3 | μ=0.36 Class DS |

| Density | ASTM D792-13 Method A,Water at 23°C | N/A | 1.15g/cm³ |

| Squareness | ASTM F2055-17 | ≤0.25mm/305mm | Pass |

| Size | ASTM F2055-17 | A tolerance of ±0.4mm/305mm | Pass |

| Thickness | ASTM F386-17 | A tolerance of ±0.13mm | Pass |

| Thermal Conductivity | ASTM C518-10 | N/A | 0.114 W/(m.K) |

| Thermal Resistance | ASTM C518-10 | N/A | 0.062(m².K)/W |

| Scratch Resistance | EN 16094B | >2,500g | 3,500g |